Idrætsudstyr!

Stort udvalg af sportsudstyr online og idrætsrekvisitter til både udendørs og indendørs brug!

Her kan I gøre et godt køb blandt vores udvalg af sportsudstyr til skoler, virksomheder og organisationer til rigtig gode priser!

Leder du efter nye fodboldmål til jeres idrætsklub?

Men har du også en række ”grønne” mål, du gerne vil nå?

Så har vi gode nyheder til dig! Vi kan nemlig nu tilbyde fodboldmål, hvor aluminiumet er lavet af 75 % genbrugsmateriale, men med samme holdbarhed og pris som almindelige mål!

Udvalgte idrætskategorier

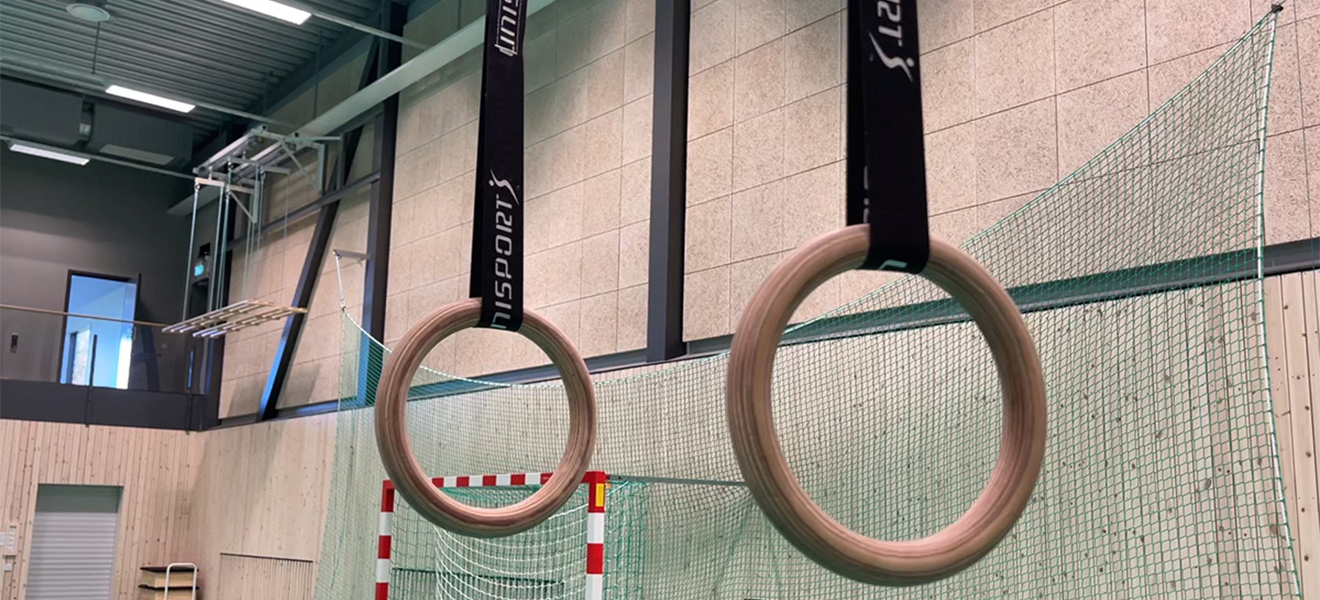

Køb sportsudstyr hos Unisport

Unisport er markedsledende leverandør af sportsudstyr til skoler, haller, kommuner og idrætsforeninger samt til større idrætsprojekter – inde og ude. Køb sportsudstyr hos os – størstedelen af vores sortiment indenfor idrætsudstyr er fremstillet på vores fabrik i Sverige, og ved at have vores egne produktionsfaciliteter kan vi garantere den bedst mulige kvalitet på vores produkter. Vi leverer idrætsudstyr til alle idrætsgrene og skaber idrætsfaciliteter i hele Norden, både indendørs og udendørs. Vores formål er, at få mennesker til at bevæge sig mere via nyskabende og inspirerende idrætsrum, og derigennem bidrage til et sundere samfund.